More news

- Asian paint regulatory round up – Indonesian exterior paint still uses lead, warns W...

- Nigeria’s paint industry navigates regulatory changes and economic challenges amid p...

- Focus on the global coatings market: Global coatings market outlook

- Ask Joe Powder – October 2024

- Chinese paint majors look to domestic consumer sales as commercial real estate slumps

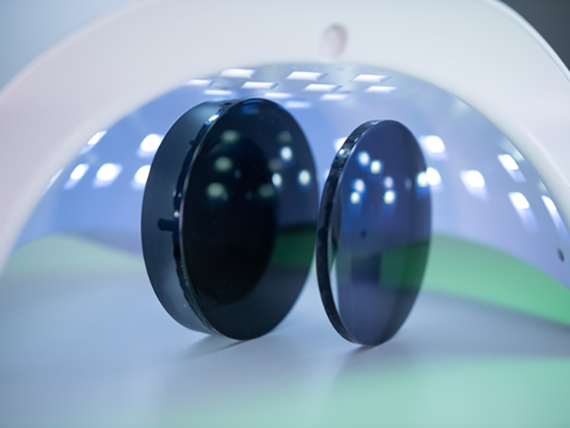

PPG has signed an exclusive supplier agreement with Flō-Optics, a developer of digital manufacturing technology for the ophthalmic industry, for the application of PPG HI-GARD® scratch-resistant coatings using Flō’s proprietary digital printing technology.

The agreement will enable the first ever digitised lens coating solutions using additive manufacturing (AM), or 3D printing, technology. The digitised process will enable ophthalmic labs to apply coatings to lenses with precision for a customisable production method that allows for lenses with unique performance capabilities. In addition to allowing lenses to be more functional, the process makes lens coating more efficient, reducing material consumption, lowering production energy requirements and offering faster turnaround times compared to traditional application methods.

“Since the inception of PPG Hi-Gard coatings, our approach has been to provide innovative, protective optical solutions that are on the cutting edge of technology,” said Zachary White, PPG Global Segment Manager, New Markets, Optical Monomers and Coatings. “PPG has a history of successfully collaborating with disruptive companies like Flō, leveraging technological and manufacturing know-how to introduce step-change advancements to the industry.”

READ MORE:

‘The sustainable factory’: PPG education partner C3 launches digital lesson

Flō’s digital coatings technology is achieved through multimaterial and multilayering techniques that expand customization and automation options, reduce production complexity, increase scalability and deliver consistent quality.

PPG Hi-Gard lens coating solutions provide a durable, scratch-resistant coating on ophthalmic lenses made from plastic lens materials. The optical quality of plastic lenses is maintained, and lenses coated with Hi-Gard lens coating are four to six times more abrasion resistant than uncoated lenses.

“Pairing PPG’s coatings expertise with Flō’s breakthrough manufacturing technology opens the door to completely transform the way optical products are designed and developed into future-ready solutions,” White said. “Flō’s technology has the potential to redefine the way optical lens products are created in prescription laboratories.”

“Flō shares PPG’s vision for a more sustainable future where lens coating stacks are created in a smarter, optimised and automated environment that expands flexibility, enhances quality and minimises complexity,” said Jonathan Jaglom, Flō Chairman and CEO. “Our path forward with PPG leverages untapped possibilities in the optical industry and draws upon our combined expertise.”

Flō will demonstrate its 3D printing technology featuring PPG Hi-Gard coatings at Vision Expo West, September 27-30, 2023, in Las Vegas. Visit the Flō team at stand #F10051.

Flō-Optics

Flō-Optics seeks to transform the ophthalmic market by providing digitised coating solutions through state-of-the-art Additive Manufacturing (AM) technology via multi-material and multi-layering techniques. This innovative approach allows ophthalmic labs enhanced possibilities regarding coating options that are both improved in terms of functionalities and offered at a lower price point. To learn more, visit www.flo-optics.com