More news

- Asian paint regulatory round up – Indonesian exterior paint still uses lead, warns W...

- Nigeria’s paint industry navigates regulatory changes and economic challenges amid p...

- Focus on the global coatings market: Global coatings market outlook

- Innovative coatings mitigate effects of deepening climate change

- Ask Joe Powder – October 2024

Evonik has launched the PlasCO2 project together with three partners. The aim is to use carbon dioxide (CO2) as a raw material in the production of C4 chemicals. The German Federal Ministry of Education and Research is funding the project with more than €1.8M. PlasCO2 stands for ‘Plasma-induced generation of carbon monoxide from carbon dioxide and its chemical utilisation’. The researchers are working on extracting synthesis gas from carbon dioxide and hydrogen by means of a plasma reactor using a newly developed process. The synthesis gas obtained in this way can then be used for the production of chemical products.

The project consortium, which is coordinated by Evonik, consists of four partners. It thus brings together all competencies, from catalysis and plasma research to plant engineering. In addition to Evonik, the Leibniz Institute for Catalysis (LIKAT), the Leibniz Institute for Plasma Research (INP), and Rafflenbeul Anlagen Bau GmbH are also involved.

"If we succeed in generating carbon dioxide as a raw material, we would not only make a significant contribution to reducing our carbon footprint, but we would also open up a completely new world of chemistry," says Professor Dr. Robert Franke, Head of Hydroformylation Research at Evonik Performance Intermediates and co-ordinator of the PlasCO2 project.

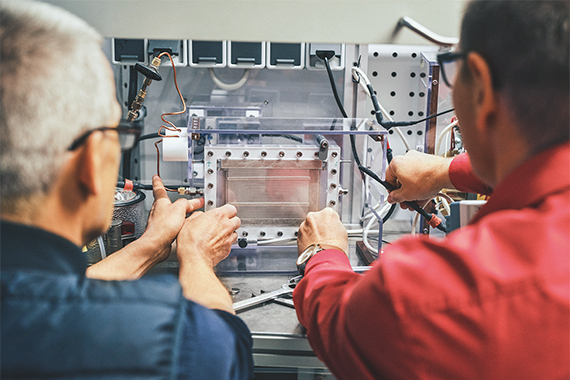

Sustainability is a key driver of the venture: At the heart of the project is the conversion of carbon dioxide with hydrogen to carbon monoxide. Low-temperature plasmas are to be used as a novel energy source, which require little energy and thus activate the inert carbon particularly efficiently. To generate these plasmas, the research group wants to develop a new kind of reactor, that can be operated with renewable energy sources. Later, these should be widely deployable and commercialisable. The synthesis gas generated in this way can be used for the production of organic compounds in C4 chemistry. These can in turn be used to produce plasticisers or petrochemical specialties, for example.

Evonik will begin with basic research, initially carrying out evaluations of eco-efficiency and economic viability as well as quantum chemical calculations. The plasma reactors used have so far been used for the purification of exhaust gas. Evonik is continuing to work on their development so that, probably after about four years, a pilot plant can be built that creates the plasma with renewable resources.

"To carry out these projects of application-oriented basic research, we at Evonik absolutely need the expertise of our partners at the research institutes and at other companies," says Dr Marc Oliver Kristen, Project Manager of PlasCO2. "Funding from the BMBF is also essential to enable us to pursue such highly innovative approaches."

Read more in the latest Elements magazine:

https://elements.evonik.com/research-and-innovation/turning-co2-into-valuable-chemicals/