More news

- Asian paint regulatory round up – Indonesian exterior paint still uses lead, warns W...

- Nigeria’s paint industry navigates regulatory changes and economic challenges amid p...

- Focus on the global coatings market: Global coatings market outlook

- Ask Joe Powder – October 2024

- Chinese paint majors look to domestic consumer sales as commercial real estate slumps

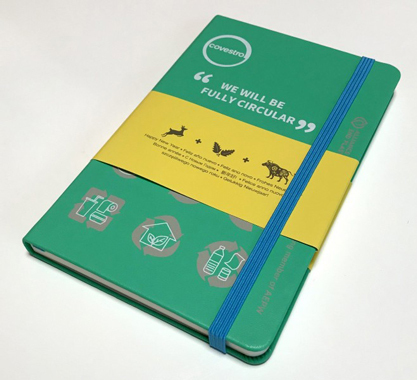

Moleskine® notebooks are replicas of the legendary notebook used by such notable people as Vincent Van Gogh, Pablo Picasso, Ernest Hemingway, and Bruce Chatwin. Moleskine places great emphasis on more sustainable products and manufacturing processes and has already been certified by the Forest Stewardship Council (FSC). For the covers of its classic notebooks, the company relies on Covestro’s advanced INSQIN®waterborne polyurethane (PU) technology for textile coating with partially bio-based raw materials. This will increase the use of alternative raw materials in the production of the PU synthetics covers.

This application focuses on waterborne PU dispersions with up to 50% biomass-based carbon content, reducing the CO2 footprint accordingly but offering the same good quality as fossil-based raw materials. The coating also features a premium look and feel – as befits the characteristic quality of these notebooks. Using INSQIN® technology, Moleskine® and Chinese PU synthetics material specialist Hexin are now able to produce partially bio-based coatings for hardcover and softcover notebooks.

On the path to more circularity

"We are partnering with Covestro to perfect these high-quality, low-solvent coatings for our classic Moleskine®notebook covers," says Daniela Riccardi, the company’s Chief Executive Officer. "Covestro’s partially bio-based coating technology enables us to reduce our impact on the environment and improve our sustainability."

"Working with innovative partners like Moleskine® allows us to develop more sustainable materials," explains Dr. Torsten Pohl, global head of Textile Coating at Covestro. "With our new partially bio-based raw material, Covestro allows for a total of approximately 23% renewable carbon in this coating, which is in line with our vision to become fully circular."

The project is part of a global strategic programme, with which Covestro is fully committed to the circular economy. That’s why the company is focusing on the use of alternative raw materials and renewable energy, the development of innovative recycling technologies, and collaboration with partners along the value chains.