More news

- Asian paint regulatory round up – Indonesian exterior paint still uses lead, warns W...

- Nigeria’s paint industry navigates regulatory changes and economic challenges amid p...

- Focus on the global coatings market: Global coatings market outlook

- Ask Joe Powder – October 2024

- Chinese paint majors look to domestic consumer sales as commercial real estate slumps

- Renewed commitment of BASF and Omya to the paper & board coating industry

- Joint use of BASF’s Pilot Coating Center for at least four more years

- Customers benefit from continued world-class technical service and coating expertise

Omya and BASF are the two market leaders in terms of raw materials for the formulation of coating colours used in the paper & board industry. Omya offers mineral filler solutions and innovative coating concepts based on Calcium Carbonate, complementary pigments and additives, for the production of paper and board. BASF supplies a comprehensive and innovative product range of binders and coating additives for the formulation of paper and board coatings.

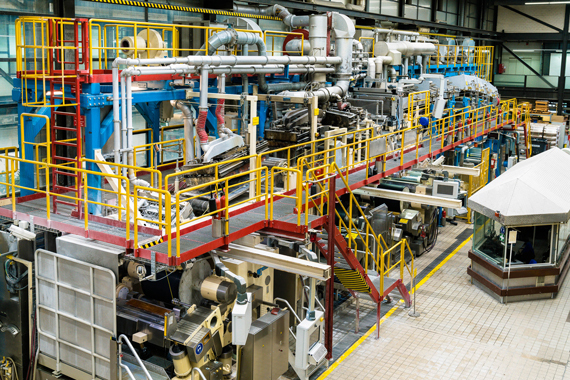

In 2003, both companies decided to join forces and bundle their know-how in the area of paper & board coating. The centerpiece of the partnership is BASF’s Pilot Coating Center in Ludwigshafen, Germany, which offers state-of-the-art pilot coating equipment – including two pilot coaters, one Supercalender and lab testing equipment – operated by a highly skilled team. The existing partnership would have expired by the end of 2021. Both Omya and BASF are now happy to announce that their existing partnership will be prolonged for a minimum of four years. Their customers will continue to benefit from world-class technical service and coating expertise of the two market leaders.

Maintaining the focus on technical service and coating expertise

"The pilot coating centre facilitates the efficient transfer of technical solutions, new product developments and optimised recipes from lab to paper mill while reducing risk. This is even more important in today’s challenging times with increased competitive and cost pressure. Reduced time-to-market and less off-spec production help our customers to save money,” says Volker Scharffenberger, Head of BASF’s pilot coating centre Ludwigshafen.

"Over the last two years we have seen that other market players reduce their service offering to the industry. For example, PTS closed its VESTRA pilot coater plant in Munich in 2019 and Trinseo followed with the closure of its pilot coater in Samstagern in 2020. Our strategy is different: We fully support our customers in formulating customised coating colour solutions in the most efficient and cost-effective way. That is why we have decided to continue utilising BASF’s pilot coating centre in the future. The discussions with BASF were straightforward since both companies follow the same market approach: Both look for the best overall value proposition with a strong focus on technical service and coating expertise as a differentiating factor,” notes Karlheinz Hurst, Director Technical Services – Paper & Board, Omya International AG.

Strong yearly investment for customers

Prof Dr Thomas Schiele, Vice President Business Management Dispersions for Adhesives, Fiber Bonding and Paper Coating, BASF: "The paper coating market in Europe is changing dramatically. On the one hand, we see a significant decline in coated graphical papers, which was accelerated by the COVID-19 pandemic. On the other hand, there is a rising demand for packaging paper and board. At the end of the day, only the fittest paper mills will survive and benefit from the change. One important part of the solution is the coating color formulation and that is exactly where we can support with our Pilot Coating Center. We invest every year several millions of euros in the maintenance and improvement of our equipment, which represents a very strong long-term commitment to the paper & board industry as well as to technical excellence in such a challenging market. At this stage, we can simulate almost all common application methods in our state-of-the-art facility, including our Curtain Coater. Even air knife applications are possible on our second, smaller coater.

Optimising coating technology to master the challenges of the future

Bernd Balzereit, Vice President Paper & Board at Omya International AG, said: "For Omya, the access to BASF’s Pilot Coating Center is an essential asset in the development of innovative paper & board packaging solutions and their proof of concept. Until today we have introduced several packaging concepts, such as recyclable barrier coatings to reduce the need for plastic packaging; or customisable coating concepts for cardboard and containerboard manufacturers to overcome white fibre shortness and to enhance print performance. We welcome all interested customers to make use of Omya’s offering for concept validation at BASF’s Pilot Coating Center. Only with strong and committed partners the challenges of the future can be mastered.”

Apart from the continued partnership, both companies will continue to market their products and services for the paper industry independently. Existing business relationships of BASF and Omya with their respective customers will remain unchanged. BASF also offers interested third parties the possibility to benefit from its excellent technical infrastructure which allows to simulate and optimise customer processes – from paper coating to printing.