More news

- Asian paint regulatory round up – Indonesian exterior paint still uses lead, warns W...

- Nigeria’s paint industry navigates regulatory changes and economic challenges amid p...

- Focus on the global coatings market: Global coatings market outlook

- Ask Joe Powder – October 2024

- Chinese paint majors look to domestic consumer sales as commercial real estate slumps

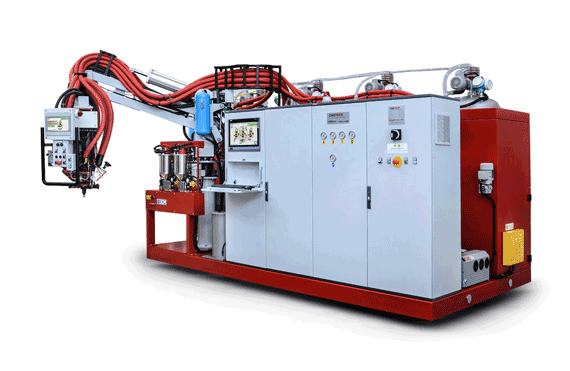

Huntsman Tecnoelastomeri has released the Castech HP3000 polyurethane casting machine – the latest model in its established range of Castech machines.

A flexible, low maintenance, equipment solution, Castech machines enable the precision metering and mixing of hot-cast elastomers and microcellular elastomer foams from all kinds of isocyanate and chain extender combinations.

Featuring a range of interchangeable parts, Castech machines can be tailor-made to suit individual customer’s manufacturing requirements.

As standard, each Castech machine provides:

- Precision dosing with good mix homogeneity

- A high output and precise shot casting capabilities

- A long size, flexible arm which makes it easy to cast parts of different shapes and sizes.

Each machine also comes with its own software package for monitoring performance variables and making adjustments during the manufacturing process.

The Castech HP3000 machine takes this functionality one step further offering:

- A high-speed motor capable of speeds of up to 10,000rpm

- An output range of 150 to 60,000g per minute, depending on circuit and pump size

- New injectors designed with higher output in mind but also capable of handling lower outputs

- A dynamic mixer, which can be standard or large in size, to provide the perfect mixing quality

- A mixing head compatible with the latest high performance polyurethane systems

- A 19-inch touch screen to display machine status

- An in-built software system for monitoring temperature, pressure levels and mixer speeds

- A cleaning system that manages solvent, pressurised air, mixer RPM and cleaning cycles, and has a programmable pre-wash to help reduce solvent consumption.

Johan van Tongelen, Global Business Director at Huntsman Tecnoelastomeri, said:

"Designed to ease equipment integration and deliver the highest levels of dosing and mixing precision, our Castech machines are among the most advanced equipment options available for the efficient manufacture of elastomers.

"With additional features available – including the option to add up to six additional injectors to the mixing chamber – the Castech HP3000 takes our offer to the next level, giving us extra flexibility when it comes to creating elastomer processing machines that exactly match our customers requirements.”

Huntsman Tecnoelastomeri is one of the world’s leading manufacturers of high-tech elastomers and elastomer casting equipment.

The business offers a bespoke, end-to-end elastomers service that offers everything you’ll ever need when it comes to selecting and processing hot-cast engineering elastomers.