More news

- Asian paint regulatory round up – Indonesian exterior paint still uses lead, warns W...

- Nigeria’s paint industry navigates regulatory changes and economic challenges amid p...

- Focus on the global coatings market: Global coatings market outlook

- Innovative coatings mitigate effects of deepening climate change

- Ask Joe Powder – October 2024

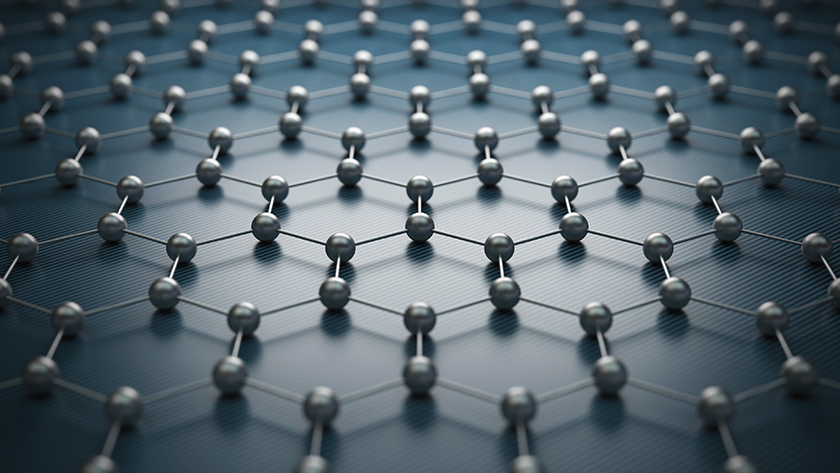

Gerdau Graphene, the nanotechnology company pioneering advanced graphene-enhanced materials for industrial applications, has announced the commercial availability of two new cutting-edge additives specifically formulated for the paint and coatings industry: NanoDUR and NanoLAV. The new additives, produced with the company’s proprietary G2D technology, utilise graphene nanoplatelets to deliver unprecedented performance improvements for water-based paints and coatings — without altering pH levels. The additives also reduce or eliminate the need for some traditional manufacturing inputs, additives and processes, which can lower production costs while improving sustainability and reducing environmental impact.

“Until recently, it has been virtually impossible for coatings manufacturers to upgrade product performance, slash manufacturing costs and improve sustainability at the same time — it simply couldn’t be done. Now, the application of carbon nanomaterials, such as graphene, in commercially available additives has made this possible and will act as a game-changer for the industry,” said Alexandre de Toledo Corrêa, CEO of Gerdau Graphene. “NanoDUR and NanoLAV represent the new performance, economic and sustainability edge for coatings manufacturers, enabling them to leapfrog competitors across the value chain. These are the newest in our growing portfolio of graphene additives and we’re excited to partner with industry leaders to develop even more novel, powerful applications for graphene.”

-

NanoDUR: enhanced durability for low- and high-traffic surfaces — NanoDUR is a water-based graphene additive that demonstrates excellent dispersion and increases paint and coating durability. NanoDUR-enhanced paints and coatings withstand wear and tear, weathering, and other external factors that can lead to degradation over time while maintaining physical and chemical properties, such as colour and adhesion, as well as a strong resistance to chipping, flaking, cracking, fading and peeling. NanoDUR is a key component of Gerdau Graphene’s C-Fix brand of graphene-enhanced paint, launched in 2022. Real-world application of C-Fix on high-traffic factory floors has shown that even with 30% less paint applied, C-Fix was 50% more durable with daily sweeper truck cleaning compared with traditional paint.

NanoLAV: improved washability and moisture-resistance in tropical and subtropical regions — NanoLAV is a graphene additive specifically designed for water-based architectural paints. With excellent dispersibility, NanoLAV increases the washability and moisture-resistance of painted or coated surfaces, enabling them to withstand cleaning or washing without degrading, dissolving, peeling or fading when exposed to water, mild detergents or other cleaning agents. The washability of a paint or coating is important in applications where hygiene is crucial, such as hospitals, schools and kitchens, and in locations that are prone to stains, dirt, and other contaminants that accumulate on surfaces. Because NanoLAV does not modify the pH of paint or coating products, it can significantly reduce or eliminate the need for high-alkaline washability promoters such as sodium silicate, which can harm aquatic life and disrupt ecosystems.

NanoDUR and NanoLAV join Gerdau Graphene’s portfolio of graphene additives for a wide variety of industrial materials and applications. The company recently announced the commercial availability of Poly-G, a collection of graphene-enhanced thermoplastic masterbatches for the plastics industry. Poly-G dramatically improves the durability and sustainability of plastic packaging films, profiles, and sheets formed by extrusion processes. Poly-G will be imported and distributed in Japan in partnership with Sumitomo Corporation.

Graphene, considered to be the strongest material on Earth, is a one to ten atom-thick sheet of densely compacted carbon that can be modified for various uses and added to industrial materials. Since its discovery in 2004, Graphene’s extraordinary chemical, physical, electrical, thermal and mechanical properties have captivated the world and led to its inventors winning the Nobel Prize in chemistry.