More news

- Asian paint regulatory round up – Indonesian exterior paint still uses lead, warns W...

- Nigeria’s paint industry navigates regulatory changes and economic challenges amid p...

- Focus on the global coatings market: Global coatings market outlook

- Innovative coatings mitigate effects of deepening climate change

- Ask Joe Powder – October 2024

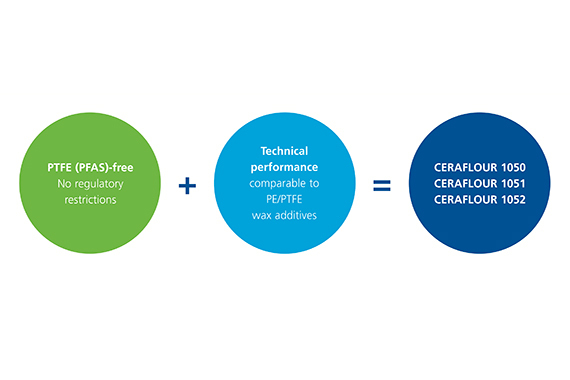

Classic PTFE-based wax additives possess special properties that other materials do not have – they offer outstanding scratch and abrasion resistance in a whole range of areas of application. For some time now, however, the use of PTFE has been viewed increasingly critically at a global level.

Because of this, BYK has developed PTFE-free wax additives that not only are safe to apply, but that also ensure outstanding application results: CERAFLOUR 1050, CERAFLOUR 1051, and CERAFLOUR 1052.

On account of their special formulation, when compared with standard additives, these additives display comparable mechanical properties in terms of scratch and abrasion resistance and of surface slip. Added to which – due to their fine particle size distribution – they are ideal for use in clearcoats and systems with low film thickness. In aqueous systems containing cosolvents, it is possible to achieve a matting effect.

All three micronised wax additives are suitable for aqueous, solventborne, solvent-free, and UV coating systems, yet they also differ from each other in their areas of application:

- • CERAFLOUR 1050 is especially recommended for clearcoats.

- • CERAFLOUR 1051 displays the best of results in a wide range of application areas.

- • CERAFLOUR 1052 is suitable for systems with low COF requirements.

These three innovative and sustainable products will play an inspiring role in the new digital BYK Live Event on May 24, 2022. Make use of this opportunity to participate with a view to increasing your knowledge lead.

You can register for the event here: live.byk.com