More news

- Asian paint regulatory round up – Indonesian exterior paint still uses lead, warns W...

- Nigeria’s paint industry navigates regulatory changes and economic challenges amid p...

- Focus on the global coatings market: Global coatings market outlook

- Ask Joe Powder – October 2024

- Chinese paint majors look to domestic consumer sales as commercial real estate slumps

Bostik’s Born2Bond™ R&D team has released details of a new cyanoacrylate-based adhesive prototype at the in-adhesives event, proving how products are being developed for a near-future that will see instant adhesives used for long-term critical applications such as those required in the automotive and electronics industry.

In the presentation, ‘New n-Butyl cyanoacrylate-based adhesive to combine flexibility, humidity resistance and low CLP’, the Born2Bond™ R&D team revealed a new two-component (2K) solution that will deliver long-term durability. It will propel Born2Bond™’s instant adhesives’ use outside of repair and maintenance applications, into a solution that can be relied upon for longer-term, structural engineering use.

This development has been achieved thanks to the use of n-Butyl cyanoacrylate (BuCa), a hydrophobic monomer that when properly formulated becomes a highly-flexible polymer, recognised as the main component of many existing instant medical grade adhesives.

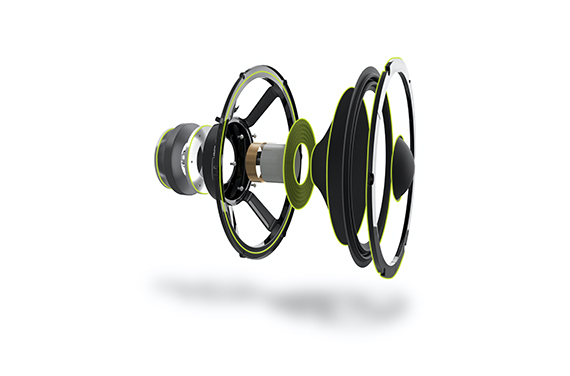

In addition to the automotive industry, other use cases will be in audio systems and wearable technology. The technology’s inherent flexible and hydrophobic qualities mean that bonding integrity is maintained even for applications where vibrating or humid environments are common, or for where impact and high levels of wear and tear are likely (such as mobile phones and smart watches). Whereas current flexible instant adhesives offer approximately 10% elongation, this new technology provides up to 100% elongation, ideal for applications that require flexing such as a tweeter found in a loudspeaker.

During the presentation, the team demonstrated how the 2K solution will enable more engineers to realise the benefits of instant adhesives, including fast-curing (generally less than one minute, depending on the substrate and environmental conditions) which can vastly accelerate the manufacturing process, thereby increasing efficiencies and productivity. They also have the benefit of delivering higher quality achieved through precise dispensing and automated and reliable process control, and durability resulting in less product failure and replacement parts, furthering sustainability.

The low-odour and low-blooming product will not carry hazard labels or CLP pictograms, enhancing working comfort and providing a more environmentally-friendly solution.

Arnau Pejoan, Engineering Adhesives R&D Team Leader, who led the in-adhesives presentation said the development of a 2K solution will realise a new era for engineering adhesives: "It will fill a gap in the market, delivering a hybrid solution for engineers needing to utilise more efficient manufacturing processes, but also requiring impact resistant and flexible results that will remain stable over many years,” he said.

"The product has been developed directly as a result of customer demand and feedback, and our team are proud to be working on a product that provides a genuinely unique proposition to the market.”

Polivio Goncalves, Bostik’s Global Head for Engineering Adhesives, said it is a critical development for instant adhesives, and one borne out of a history of embedded in cyanoacrylate innovation: "Our parent company Arkema made a significant investment in CMC (Crackless Monomer Company) so we could accelerate the development and production of high value-added engineering adhesives. The investment complemented the acquisition of Afinitica in 2018, which saw the expansion of our range of instant engineering adhesives manufactured through the patented ‘crackless process’,” he explained.

"It was these acquisitions, and the investment in dedicated expertise that has enabled us to develop this market-first solution.”

The prototype is in the final stages of development and for businesses looking to become part of this innovative engineering adhesive solution, samples can be produced for customer testing.

The hybrid in-adhesives event took place virtually and in-person in Munich, May 12-13 2022.