More news

- Focus on the global coatings market: Global coatings market outlook

- Innovative coatings mitigate effects of deepening climate change

- View from the UK: Navigating chemical policy and sustainability

- Focus on adhesives: Unveiling unbreakable bonds – Testing redefines physical strengt...

- Focus on adhesives: Henkel and Covestro collaborate for sustainability of engineered wood ...

Artur Palasz, Spektrochem, discusses how to select bio-based dispersing additives for architectural, wood and DTM coatings and the challenges involved when replacing a traditional fossil-based chemical compound with a bio-based option

Green transformation and sustainable development also include raw materials, which are consciously being replaced more and more often from conventional to bio-based ingredients, including in waterborne paints. Although these paints are considered to be more eco-friendly than solventborne paints, tradition ingredients of latex paints also require revision and consideration of the use of greener options, such as being obtained fully or partially from renewable resources, produced using green energy, recycled, etc.

One of the ingredients of latex paints that can increasingly be found on the market as bio-based is dispersing additives. These are the key ingredients in the formulation of waterborne paints, both in the case of architectural paints, wood coatings containing pigments and fillers, but also direct-to-metal paints.

Dispersing additives are responsible for ensuring the possibility of preparing paints with pigments and fillers, stabilising their particles during storage and many interactions with other ingredients of the formulation, including thickeners and binders. As surfactants, they are an extremely important element of every formulation, hence their selection must also be given appropriate attention at the stage of laboratory tests. However, with such an important component of the formulation as dispersants, it is not easy to replace the traditional dispersant, which is a conventional chemical compound, usually fossil-based, with a new bio-based one, usually with a completely different chemical composition.

Changing the dispersant may cause many problems, such as with the dispersibility of the pigments and fillers used and the entire paint production process, changes in key parameters such as rheological properties, viscosity drift over time, loss of compatibility with pigments in the case of tinting bases, change in scrub resistance, impact on gloss, etc. Therefore, changing the dispersant is a big challenge for the formulator, and it can be made easier by providing appropriate knowledge from application studies showing how to best go through the process of changing formulations using exemplary case studies and guideline formulations.

Conventional vs bio-based

Conventional dispersing additives range from the simplest chemical bases of sodium polymethacrylate, through to more developed polymer block dispersants and sequential additives, to hyperdispersants that are used to disperse carbonate fillers, functional fillers, titanium dioxide pigments or organic pigments. Conventional dispersants are mostly produced from fossil fuels or their derivatives, which contributes to the burden on the environment (use of exhaustible resources, carbon footprint, etc.). Their effectiveness and performance is well known and requires laboratory tests but their use in formulations is much easier. They are also cost-effective and allow for long-lasting performance of paints.

Bio-based dispersants, in turn, are additives mostly based on completely different chemical bases that cannot be replaced 1:1. Their advantage is not only a more environmentally friendly formula or a production process using renewable resources, it is also a smaller carbon footprint, fulfilment of the sustainability requirement, in many cases biocide-free 14C bio-based composition and a number of other benefits, such as easier Ecolabel certification of the final paint, etc. There are also some limitations and disadvantages that cannot be ignored. These include the definitely limited quantity on the market, low cost effectiveness and, above all, the need to perform a large amount of research to find the appropriate performance in the formulations and to be sure that the performance is the same/better than the conventional equivalent used.

In order to avoid greenwashing and the use of bio-based additives, including forced dispersants, it is necessary to analyse to what extent it will be possible to introduce a new additive to the formulation and how expensive it will be in the context of the need to change the formulation and the incurred R&D costs. It will be necessary to co-operate closely with external research units and labs that are able to practically consult, through application studies, the process of introducing such dispersants to the market, which over time will lead to a reduction in the cost of this type of additives and make them widely available – the green transformation in the paint industry today is at the initial stage, but in the long run it is a necessity to make another contribution to caring for the planet.

READ MORE:

Special report: Regulators cracking down on greenwashing worldwide

Dispersing process

Dispersing additives work effectively by creating a double electrical layer that causes pigment and filler particles to repel each other (Figure 1). The interaction between these electrostatic forces and the attractive London-van der Waal forces is described by the DLVO theory.

Figure 1. Schematic effect of a dispersant additive on a filler/pigment particle

For more theory, I invite you to the books, and in this article I will focus on the practical assessment of the effectiveness of dispersing additives in the formulations.

However, for the dispersing theory to work, it is not enough to just add a dispersant additive. A number of points must be met, starting from the fact that a given additive must act as a dispersant, i.e. reduce the viscosity of the mill-base during grinding. For this to happen, an appropriate chemical base is needed, the dose at which this effectiveness is best, as well as the conditions carrying out this process, such as the concentration of pigments and/or fillers, appropriate equipment, high power and the speed of setting the pigment and filler particles in motion. But first, I would like to explain the terms I will use in this article. As you have already noticed, I used the term grinding, but also dispersing.

When we use pigments or fillers to produce paints, they are in the form of powder, which is composed of particles of a specific size. Due to the crystalline nature of these raw materials, they are in the form of aggregates and agglomerates, i.e. clusters of primary particles (aggregates) and clusters of aggregates (agglomerates). In the terminology of paints and the production process, dispersing is understood as the mechanical disintegration of agglomerates that occurs as a result of high-speed mixing (high-speed dispersing). Grinding is the process of disintegrating aggregates with air between the particles. The disintegration of these particles is possible by ensuring appropriate high-speed dispersing, and must also be supported by the action of agents that replace the air between the particles of the medium with reduced surface tension, which in turn is referred to as wetting. Grinding can only occur if there is a sufficient concentration of particles in the mill base, so that high-speed dispersing causes them to vigorously collide and rub against each other. In the case of latex paints, this is achieved by building a high concentration of slurry for fillers, pigments (dispersed and ground together or separately), e.g. above 80wt%, or in the case of, for example, pigment concentrates in which such concentrations cannot be obtained, they use grinding in an additional medium such as beads, in ball mills that cause the breakdown of these aggregates.

Everyone in the paint industry is familiar with the diagram presented in Figure 2, which shows the dimensions of the cowles dissolver container along with the dimensions of the blade (serrated disc) and bottom access, diameter dependence, etc. This diagram is extremely useful for designing the grinding process in cowles dissolver to ensure adequate flow and particle movement in the vessel caused by the high-speed dispersing blade (saw disc impeller).

Figure 2. Diagram of vessel dimensions in cowles dissolver for ensuring flow during grinding

The flow should take place in such a way that there are no dead spots (stasis) and the flowing mill-base should form toroidally in the shape of a donut (Figure 3). This is why it is necessary to select the appropriate dose of the dispersant, which will ensure the maximum reduction in mill-base viscosity, allowing for a high loading of solids (pigments and fillers), which will result in good collision of particles during grinding and their effective separation into primary particles and stabilisation as described in the theory of dispersing [1].

Figure 3. Donut-like flow in vessel while grinding in dissolver

It is also crucial to take into account parameters such as foaming properties of the dispersant in water. This is important from the point of view of the need to add a defoamer and select it appropriately to eliminate foam at the stage of initial introduction of pigments and fillers into the mill-base, where there are no such shear forces ensuring proper incorporation of the defoamer.

Finding the best dose

Determining the best dispersant dose is a multi-step procedure. Firstly, after selecting the dispersant additive and ensuring that it will reduce the viscosity of the mill-base, the effectiveness range is established, which usually includes the lowest point to which viscosity reduction is possible, but also dispersibility tests are carried out in terms of flow, elimination of dead spots during donut-like flow (Figure 4). The next step is to check how the most effective doses ensuring viscosity reduction affect the performance parameters of the prepared paints with specific assumptions.

Figure 4. Example of poor flow caused by incorrect flow (left) and correct flow (right)

The next step in determining the dispersant dose is to check the effect on the key parameters of the designed paint. The influence of the dispersant can be noticed starting from such obvious parameters as viscosity, storage stability, compatibility with pigment concentrates, but also due to the fact that these are surfactants, the influence on scrub resistance, gloss, dirt pick-up cannot be ignored, if it is important for the designed paint.

Due to the complicated nature of such application studies, it is necessary to rely on guideline formulations showing comparisons between dispersants, especially when we want to replace a conventional dispersant with a bio-based one based on a new chemical composition. The following part of the article discusses an example of a project that was carried out in our laboratory for one of the producers of such dispersants in order to compare the effectiveness of a typical dispersant from the US market with a newly designed bio-based dispersant [2].

Experimental

The aim of the project was a comparative assessment of the performance of a conventional dispersant, a simple dispersant typically used in the paint industry for the production of waterborne architectural paints, with a newly developed 100% bio-based dispersant. Their effectiveness was checked on a ladder in doses ensuring the lowest mill-base viscosity (the first stage of the lab work), and then a comparison of the impact on the properties of paints marked as key performance features (second stage).

READ MORE:

Focus on automotive: Automotive industry transforms towards sustainability model

Dispersing agents for studies

The dispersants differed in their chemical base, content of active ingredients and tendency to foam. The characteristics of the dispersant samples for testing are presented in Table 1.

| Table 1. Characteristics of dispersants for application studies | ||

| Properties | Typical value | |

| Conventional

fossil-based dispersant |

New surfactant

BIO-dispersant |

|

| Chemical base | Sodium polymethacrylate | Proprietary |

| Active solids | 25.0 % ± 2.0 % | 80.0 ± 2.0 % |

| Weight per US gallon / density | 9.6 lbs/gal | 9.1 lbs/gal |

| Viscosity | max. 75 cps | max. 600 cps |

| Solubility | Soluble in water | Soluble in water |

| Foaming (RMFA test) | No foaming | Significant tendency to foaming |

Formulation

The Spektrochem laboratory implementing the entire project, the formulation presented in Table 2 and samples of mill-base and dyes described in the following sections were prepared.

| Table 2. Interior latex paint formulation PVC 37% | ||

| Ingredients | Weight, lbs | |

| Grinding – mill-base | ||

| Demineralised water

Dispersing agent In-can preservative Defoamer Titanium dioxide pigment Ground calcium carbonate filler Total |

207.1

X 1.6 0.8 395.3 395.3 1,000 lbs |

|

| Let-down | ||

| Acrylic latex dispersion

Mill-base Demineralised water Fungicide Flash rust inhibitor (can protection) Attapulgite suspension – thickener HEUR thickener Total |

544.1

544.1 14.7 2.4 2.4 86.1 6.5 1,200 lbs |

|

| PVC: | 37 vol% | |

| Volume solids: | 47 vol% | |

| Weight per US gal: | 12.0 lbs/gal | |

X The doses of the dispersant additives were determined on the basis of the tests described in the following section

The formulation was prepared to determine the impact of a conventional fossil-based dispersant additive and a new bio-based dispersant on parameters such as:

- Dispersibility, including mill-base viscosity reduction in ladder dosing and finding the most effective viscosity-reducing dose, and then use it to prepare paints from the formulations as in Table 2 and evaluate the paint parameters;

- Compatibility with polymer dispersions as binders;

- Scrub resistance;

- Washability;

- Colour acceptance.

Dispersibility

The broadly understood dispersibility parameter should be understood as the ability to create a dispersion of pigments and fillers during grinding while obtaining the lowest viscosity level at the maximum expected mill-base loading. In the case of the formulation used for testing, titanium dioxide and a filler in the form of GCC (ground calcium carbonate) with specific grain characteristics were used as the pigment. In this case, it was assumed that the loading into the mill-base would be approximately 80 wt%. Grinding was carried out using a lab-scale cowles dissolver equipped with a serrated disc (Figure 5). Data collected during dispersibility research is presented below.

Figure 5. Lab-scale dispersing and grinding station in the Spektrochem lab

The prepared mill-base was grinded with ladder doses of fossil-base and bio-based dispersant and their viscosity was compared using the ASTM D2196 method A immediately after preparing the slurry. The viscosity measurement results are shown in Figure 6. As you can see, the graphs differ significantly in their location, which means that the effectiveness of the fossil-based and bio-based dispersants is completely different. This shows, first of all, that there can be no question of a 1:1 change, even though the doses determined for the tests were selected by converting each dispersant into active parts and pigments and fillers in the mill-base. The fossil-based dispersant has the lowest viscosity level when dosing from 0.25% to 0.50% (active ingredients to the sum of pigments and fillers in the mill-base), and the remaining doses have higher viscosities. However, it can be seen that the increase in viscosity in doses from 0.50% to 1.25% is quite mild and the slurry still has a low viscosity in each case (the exception is the significantly higher viscosity at the 0.1% dose).

Figure 6. Results of mill-base viscosity measurements with fossil-based and bio-based dispersants

In turn, the bio-based dispersant did not allow for such a wide dosage spectrum, because by dispersing and grinding it was possible to prepare only three doses of 0.50%, 0.75% and 1.00% (active ingredients based on the sum of pigments and fillers in the mill-base), because the remaining doses resulted in a complete inability to incorporate titanium dioxide and filler in the assumed concentration necessary for good grinding. Marginal doses, e.g. 0.25% and 3.00%, made it impossible to introduce assumed amount of bulk ingredients into the mill-base load (Figure 7).

Figure 7. Pictures showing siltation in marginal doses for bio-based dispersant

It should be noted that although doses in the range of 0.50% to 1.00% enabled the measurement of viscosity, the degree of grinding obtained is not satisfactory. During the grinding process, there were blind spots and problems with the flow and obtaining the donut shape of the grinded batch. The lowest viscosity obtained for a dose of 0.75% of the bio-based dispersant is indeed the lowest among the tested points where slurry preparation was possible, however the mill-base viscosity is drastically high (19,000mPa ∙ s compared to the viscosity at the lowest dose for fossil-based dispersant of approximately 550 mPa ∙ s).

The differences in the pourability and flow of individual doses of dispersants in the mill-base are presented below for a better illustration. Figure 8 shows all doses for the fossil-based dispersant and Figure 9 for the bio-based dispersant after pouring the slurry onto the dishes immediately after preparation.

Figure 8. Slurries with fossil-based dispersant poured onto dishes

Figure 9. Slurries with bio-based dispersant poured onto dishes

It is clearly visible that the flowability of the fossil-based dispersant looks completely different compared to the obtained slurries based on bio-based dispersant. This translates not only into mill-base viscosity, which is crucial for obtaining appropriate grinding at high concentration, which should be understood directly as the effectiveness of the dispersant, but also into difficulties in the grinding process in the case of lower power production equipment, as well as the need to grind longer, with the expenditure of more energy, the need to cool the charge because grinding with such high viscosity and the lack of sufficient evaporation of the aggregates will result in higher energy consumption and an increase in temperature during grinding. Here, data on the need to increase speed during grinding and the measured batch temperatures are presented in Table 3 for fossil-based dispersant and in Table 4 for bio-based dispersant.

| Table 3. Grind speed and temperature data for mill-base with fossil-based dispersant | ||||||

| Parameters marked during grinding | 0.1 % | 0.25 % | 0.50 % | 0.75 % | 1.0 % | 1.25 % |

| Peripheral speed, ft/min | 984 | 669 | 866 | 866 | 1,063 | 1,299 |

| Mill-base temperature after 15 min grinding, °F | 95 | 73 | 73 | 82 | 95 | 100 |

| Table 4. Grind speed and temperature data for mill-base with bio-based dispersant | |||||

| Parameters marked during grinding | 0.25 % | 0.50 % | 0.75 % | 1.0 % | 3.0 % |

| Peripheral speed, ft/min | A | 1,437 | 1,653 | 1,968 | A |

| Mill-base temperature after 15 min grinding, °F | A | 100 | 113 | 136 | A |

A Incorporation of all fillers and pigments impossible due to very high viscosity during slurry preparation

Comparing the results in the tables, it is clear that for grinding the same mill-base using bio-based dispersant, it was necessary to use much more energy and power, which results directly from the data on peripheral speed during grinding, and it is also visible that during such an energy-intensive process released at a much higher temperature compared to fossil-based dispersant. At this point, it is clear that the idea of bio-based and sustainability in the tested case has a big disadvantage because the use of the bio-based dispersant used in the tests will require much greater energy expenditure in the production process of paints. With such an increase in temperature (above 100°F), it is necessary to cool the mill-base to minimise the evaporation of water from the surface of the vessel, as well as to avoid destabilisation of some in-can preservatives, which lose their efficiency at high temperatures and are necessary for use in the mill- base.

However, for the purposes of further tests and paint preparation, doses were selected that ensure the lowest mill-base viscosity, 0.25% for the fossil-based dispersant and 0.75% for the bio-based dispersant (calculated into active ingredients and the sum of pigments and fillers in mill-base) and with such quantities, paints were prepared for further tests.

Compatibility with polymer dispersions

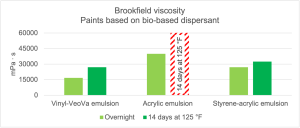

In order to check how fossil-based dispersant and bio-based dispersant (fixed doses) interact with polymer dispersions, and more precisely with the surfactants present in them, a compatibility test with three polymer emulsions as binders for latex paints was carried out. Vinyl-VeoVa, pure acrylic and styrene-acrylic copolymer emulsions were used. The paints were prepared by let-down as in the presented formulation (see Table 2) and adjusting the amount of dispersion to solid content to maintain PVC in all paints. Then, viscosity and other tests were performed (other tests were described in the cited report [2], the content of which is available on request) to determine compatibility with individual binders. The viscosity measurement results are shown in Figure 10 (paints with fossil-based dispersant) and Figure 11 (paint with bio-based dispersant).

Then, the samples were subjected to a 14-day storage stability test to check whether there was any viscosity drift as a result of accelerated aging of the liquid sample. The results are placed on the same charts for comparison.

As seen in Figure 10, compatibility with the vinyl-VeoVa copolymer emulsion has the best results. For pure acrylic and styrene-acrylic emulsions, the increase in viscosity is quite high, but it is still within the acceptable viscosity level. This is a sign that even a well-known fossil-based dispersant is not always compatible with all binders and their surfactants, and it is necessary to prepare appropriate application studies for this type of conventional additives to provide the formulator with the necessary knowledge about the performance of the formulations.

Figure 10. Viscosity of paints with various binders and fossil-based dispersant

In turn, when comparing the compatibility of paints with a bio-based dispersant, it can be seen that the high viscosity of the initial slurry prepared for paints resulted in a high initial viscosity of the paints. You can also see that the compatibility situation is slightly different compared to fossil-based dispersant. Paints with vinyl-VeoVa emulsion show a greater increase in viscosity after storage stability test, while paint based on styrene-acrylic emulsion is more compatible. The most drastic graph shows the change in the viscosity of the paint based on pure acrylic emulsion. It turns out that the bio-based dispersant interacted with the surfactants and particles of this dispersion so much that the paint completely failed the storage stability test and the viscosity increased so much that measurement is impossible (Figure 12).

Figure 11. Viscosity of paints with various binders and bio-based dispersant

The paint with bio-based dispersant and acrylic polymer emulsion also experienced a further uncontrolled increase in viscosity for samples that were sent for further laboratory testing, and after just 10 days in the laboratory it looked similar to the one after the storage stability test shown in Figure 12. These results show a completely different compatibility bio-based dispersant and also show how important such tests are to dedicate them to various binders, showing where compatibility is good and where, unfortunately, the use of a given dispersant is limited, which is especially important in the case of new and bio-based additives. Only compatible samples were taken for further tests, and pure acrylic dispersion paints were rejected.

Figure 12. Failure of paint with bio-based dispersant and acrylic binder after storage stability test

Scrub resistance

The scrub resistance test is conducted to determine in this case the influence of the surfactant on the reemulsification of the coating and increasing its susceptibility to wet abrasion during the scrub resistance test in accordance with ASTM D2486 method B (comparison between coatings). After the standard conditioning time and conditions specified in the ASTM standard, the coatings are tested using a nylon brush, an abrasive medium and scrubbed on a washability machine with shim under the coating until the number of cycles to failure is reached.

The results are presented in Figure 13 and two conclusions are clearly visible. The first is a much higher scrub resistance for paint samples with vinyl-VeoVa emulsion binder, which is caused by higher hardness and other surfactants present in the binder. The second conclusion is a visible improvement in scrub resistance with the bio-based dispersant used. both in the case of vinyl-VeoVa emulsion and styrene-acrylic emulsion as a binder. For the vinyl-VeoVa binder, the result was above 100% in the comparison between fossil-based and bio-based dispersants, and in the case of the difference between these dispersants used in the paint with a styrene-acrylic binder, an almost 350% better result was recorded for the sample with bio-based dispersant.

Figure 13. Scrub-resistance results and exposed substrates after scrub-resistance tests

Washability

Washability test is an assessment that involves washing the soilant coating with a medium using a washability machine and a standard loaded cellulose sponge and a non-abrasive medium in 4 series of 25 cycles in accordance with ASTM D3450. The result is percentage reflectance recovery calculated from reflectance measurements using a reflectometer and from measurement results on coatings before the application of soilant medium and after the washability test. It is used to determine, among others, the influence of raw materials flowing onto the surface of coatings and influencing the properties of the coating surface, including dispersants.

The test results are shown in Figure 14. Pictures clearly show the influence of the type of binder used in the tests, with the benefit of the styrene-acrylic emulsion in both cases of dispersants. There is also a noticeable, but not negligible, difference in favor of the bio-based dispersant, which allows for higher percentage reflectance recovery.

Figure 14. Measurement results of reflectance recovery after washability test

Colour acceptance

A test showing how the dispersant used to prepare paints that are also bases for POS-tinting affects the acceptance of pigment concentrates is colour acceptance, performed in this case in a simplified version, as a rub-out on freshly drying coatings applied by automatic drawdown on contrast charts. The results are shown in Figure 15, comparing the differences in colour tone at the rub-out test site. Tinting was performed using waterborne colourant based on PR112 pigment at a dosage of 2 fl.oz./US gal.

As can be seen from the results, in general each sample should be considered for the use of additional colour acceptance aid, however one result stands out, showing that it was possible to achieve relatively satisfactory colour acceptance in the case of paint based on styrene-acrylic emulsion and bio-based dispersant.

Figure 15. Results of differences in colour development after rub-out tests

Summary

The results presented in this article show that in the case of the tested bio-based dispersant as a general representative of this group of additives, interesting results can be obtained, of course also including those of not entirely good performance.

This article should be a kind of indication that in the case of both early R&D work on new bio-based raw materials, especially additives, extensive application research should be carried out in formulations taking into account real-life requirements for the paint production process, as in the case of the presented dispersants, as well as the requirements for parameters necessary to interest the paint industry in additives that are currently reluctant to be tested, such as all bio-based additives.

The presented results show that good results can be obtained, often even surprisingly good, compared to typical conventional additives, but there is still a long way to go for producers of such raw materials. It is important that it is supported by such projects that allow for the introduction to the market of only truly green additives that give an advantage, but above all, ensure appropriate performance in the formulations.

References

[1] A. Palasz, Challenges in the selection of bio-based dispersing additives for architectural paints, Chinacoat 2023, Tech Talks (VoD – Video on Demand), Shanghai, China, November 15-17, 2023

[2] Comparison of the effectiveness of fossil-based and BIO-based dispersant in the formulation of latex paints PVC 37%, June 7, 2023, Spektrochem Report to the BIO-dispersant comparison project, April 2023

Author: Artur Palasz, Ph.D., SPEKTROCHEM – Technical Center of Raw Materials for Architectural Paints, Poland

e-mail: artur.palasz@spektrochem.pl