More news

- Nigeria’s paint industry navigates regulatory changes and economic challenges amid p...

- Focus on the global coatings market: Global coatings market outlook

- Ask Joe Powder – October 2024

- Chinese paint majors look to domestic consumer sales as commercial real estate slumps

- Architectural coatings in Nepal and Bhutan

Swinburne University of Technology and Sparc Technologies Ltd are teaming up in an innovative collaboration, spearheading the evolution of smart coatings through the Australian Research Council (ARC) research project.

This partnership aims to revolutionise key industries, including aerospace, infrastructure, space exploration and renewable energy, the ASX-listed company said in a news release.

Traditionally, composites have been passive and unresponsive, but the integration of graphene is introducing a new era of “smart” materials capable of sharing information and dynamically responding to their environment, Dr Nishar Hameed, the Chief Lead Investigator in this research, explained.

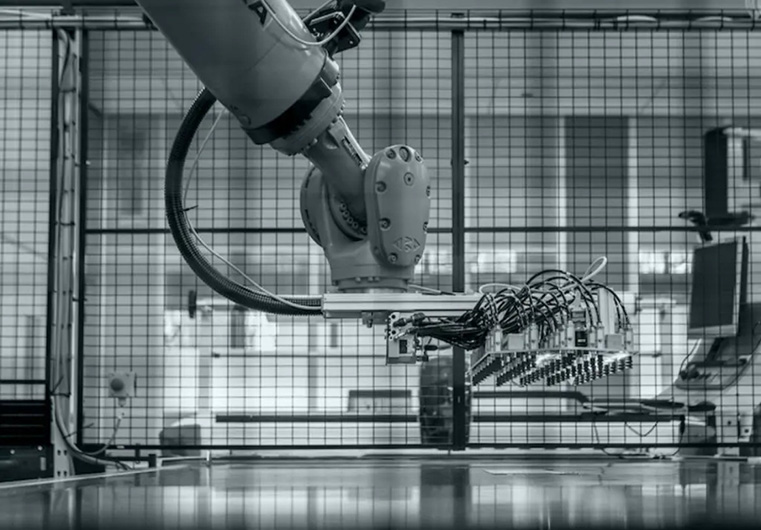

Sparc Technologies, a leading Australian producer of graphene additives, said it is spearheading the charge in developing groundbreaking technologies in coatings and composites.

The company’s state-of-the-art facility enables the mass production of its revolutionary graphene additive, ecosparc, positioning Sparc Technologies as a global leader in graphene-based solutions.

READ MORE:

Denis Wright, General Manager of Graphene Materials at Sparc, expressed excitement about the project, stating, “It is a very exciting opportunity to be contributing to this project and developing Ecosparc additives that will impart through their intrinsic properties, intelligence into coatings and composites.”

Central to this groundbreaking evolution is graphene, capable of being transformed into nano-platelets, facilitating cost-effective mass production.

Leveraging its electrical conductivity, the integration of even small amounts of graphene introduces conductivity, sensory capabilities and intelligent functionality to a diverse range of coatings and composites.

This innovative approach also unleashes a wide range of capabilities, encompassing built-in sensors, radiation protection, energy storage, performance monitoring, and data processing. Simultaneously, it reinforces structural resilience.

The collaborative project aims to test different grades of graphene-based additive formulations developed by Sparc for their performance and effectiveness in multifunctional coatings.

According to Sparc, this effort will contribute new knowledge and critical requirements for manufacturing scalable graphene formulations for the coatings and composite industries.

Image credit: Sparc Technologies Limited