The moisture content in unwrapped control meat stayed constant from day 0 to day 8, but an increase was observed after days 11 and 15. However, the differences were not significant (

p < 0.05). The values were from 75.3 to 76.9% and indicated a fresh, high-moisture product. Biobased packaging resulted in decreasing values of moisture content for all determinants. This can be attributed to the hydrophilic nature of pectin films [

12,

54], which resulted in the adsorption of moisture from poultry meat during storage. The values ranged from 75.3 to 66.5% for pectin films without nanoparticles, and similar ranges were observed for films containing commercial nanoparticles and those prepared from tomato extract. There was less reduction in moisture when films incorporated with ZnO synthesized with passionfruit extract were used (75.3–69.5%) compared with the ones with ZnO from tomato extract but not with pristine pectin or with pectin incorporated with commercial ZnO NPs. The differences between the samples were due to the interactions and compatibility of the components, which may vary based on the nanoparticle origin and characteristics.

There was a significant difference in pH values (

p < 0.05) in the unwrapped poultry meat samples during storage. From day 0 to day 15, pH values gradually increased from 5.96 to 7.62. This was the most dynamic change in the pH values among all analyzed samples, as the surface of the control samples was easily exposed to water vapor, dirt, and microorganisms. The pH increase can be associated with the production of volatile basic components due to microbial growth, the denaturation process, and the consequential release of amines and ammonia [

55]. The obtained results concerning the increase in pH values in the analyzed poultry meat (unwrapped) were in agreement with those reported by Eldaly et al. [

56] and Amjadi et al. [

57]. Moreover, the initial pH of the poultry meat is in agreement with results presented in the literature of values ranging from 5.2 to 7 [

24]. Biobased packaging limited the pH increase over time, probably due to inhibition of the growth of bacteria and protein denaturation (in agreement with the results presented in Table 1 and discussed in Section 3.2.1). Pectin films both without and with the addition of ZnO nanoparticles showed a significant effect in reducing pH values and making the samples more acidic, which can be related to the production of lactic acid by lactic acid bacteria. On each day, the pH values of control were higher than the pH of the wrapped meat. The lowest pH values (5.16–5.17 by 15 days of storage) were observed for poultry meat wrapped with films incorporated with zinc oxide commercial nanoparticles and those obtained from tomato extract. The intensity of changes in the pH values of chicken meat was somewhat different from those obtained by others. Meindrawan et al. [

58] reported that the applications of biocomposite edible coating based on bovine gelatin incorporated with ZnO nanoparticles maintained the pH of fillets at 6. These observations were also confirmed by Naveen et al. [

59] for chicken meat when using polymer composite packaging films embedded with zinc oxide nanoparticles. However, Souza et al. [

12] noted an increase in pH values for control and wrapped chicken meat with chitosan-based films incorporated with zinc oxide nanoparticles during storage. The authors observed that the biobased packaging delayed the increase in pH values, which was greater at higher concentrations of ZnO nanoparticles.

The titratable acidity, expressed in % of oleic acid equivalent, increased over time for all samples of chicken meat except on days 11 and 15 for control. For these samples, an increase from 3.80 to 4.10 and 4.27 on days 4 and 8, respectively, was observed, and then a reduction to 3.26 and 2.88, respectively. This decrease was expected, as it correlates with the increment observed in the pH values. The meat protected with biobased packaging presented higher values of titratable acidity, which was the most noticeable for pectin films without ZnO nanoparticles. These results also agree with the reduction in pH values observed for the wrapped poultry meat. The results also indicate that the rate of acidity increment was lower when ZnO was added to pectin.

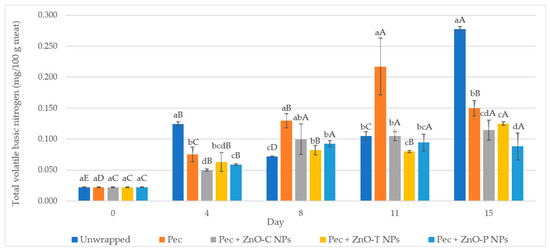

The results of the total volatile basic nitrogen (TVB-N) content in poultry meat (Figure 2) are also in agreement with the results reported for pH, acidity, and microbiological growth. Indeed, TVB-N is an indicator of meat spoilage, which is related to protein breakdown by microbial development and enzymatic action, which produces ammonia and amines, among other alkaline substances containing nitrogen [

55,

60]. Therefore, the increment in TVB-N is associated with the degradation and decomposition of poultry meat. This increment was observed for all the samples, both unwrapped and wrapped, with significance (

p < 0.05) and with an initial value of 22 mg/100 g poultry meat. Yet, the release of TVB-N throughout storage time (15 days) was significantly slower for the wrapped meat. At 15 days of storage, unwrapped poultry meat presented a value of 278 mg/100 g poultry meat, a much higher result than the results presented by wrapped meat (88–150 mg/100 g). Interestingly, the protected meat with pristine pectin films also showed a significantly higher (

p < 0.05) TVB-N value than the pectin films with ZnO nanoparticles, thus indicating the capacity of ZnO to reduce the degradation process of poultry meat and to enlarge poultry meat shelf life. The same conclusion was reported by Suo et al. in their work, wherein fresh pork meat protected with carboxymethylcellulose (CMC) film either incorporated with ZnO NP or not was monitored for a long time in cold storage [

55]. The same trend was also observed by Souza et al. [

24], who incorporated ZnO NPs synthesized with apple peels into chitosan films to protect poultry meat. Among the different NPs, passionfruit bionanocomposites presented the lowest TVB-N value at 15 days of storage, in accordance with the data observed for the

Enterobactereacea (Table 1), where poultry meat wrapped with pectin incorporated with zinc oxide nanoparticles obtained from passionfruit extracts (ZnO-P NPs) also presented the lowest values at day 15.

The high content of unsaturated fatty acid in poultry meat makes it susceptible to oxidation processes [

61]. During this oxidative degradation, lipids, vitamins, and pigments are oxidized, leading to food odor and flavor alterations, with possible concurrent production of toxic compounds that may cause a threat to food safety [

62]. These processes, together with microbiological growth, contribute to the deterioration of fresh poultry meat, reducing its shelf life. The Thiobarbituric Acid Reactive Substances (TBARS) Index and poultry meat color were two parameters analyzed to assess the oxidative processes in the poultry meat during the 15 days of storage. The results of the TBARS showed an increment over time for all the samples (

p < 0.05), a result that was expected given the nature of poultry meat. For the majority of the samples, from day 11, the results were higher than the off-flavor trash-hold value (0.5 mg MDA/kg), which is rated as the indicator of rancidity [

32]. Yet, poultry meat wrapped with pectin incorporated with zinc oxide nanoparticles obtained from passionfruit extracts (ZnO-P NPs), reached this value earlier (day 8), and poultry meat wrapped with pectin incorporated with commercial ZnO nanoparticles reached this value only on day 15. In this case, the oxidative process was delayed for several days in this bionanocomposite compared with the other biobased films and with unwrapped samples. This result can be attributed to the higher barrier of pectin to UV light and O

2 caused by the incorporation of these ZnO commercial nanoparticles, as was observed by Baek and Song [

63] with films based on

Gracilaria vermiculophylla extract incorporated with ZnO NPs, which delayed the oxidation process of smoked salmon. The same trend was also registered when poultry meat was wrapped with low-density polyethylene (LPDE) incorporated with Ag and ZnO NPs [

64]. Pristine pectin film did not retard the oxidation processes of the meat compared with unwrapped meat, although some authors mentioned the good barrier properties of pectin to oxygen [

47]. When testing chitosan in a similar assay with poultry meat, chitosan showed a deacceleration of the oxidative process [

24], which was not observed with pectin in this assay. The differences in the behavior of chitosan and pectin can be attributed to differences in O

2 permeabilities.

According to Souza et al. [

12], chitosan O

2 permeability reached a value of 0.28 × 10

−16 mol.m/m

2.s.Pa and pectin had a much higher value of 1.12 × 10

−16 mol∙m/m

2.s.Pa. In addition, contrary to what was observed in terms of microbial growth, the incorporation of ZnO NPs synthesised from tomato extracts and passionfruit extracts also did not contribute to reducing the oxidative processes in poultry meat compared with unwrapped meat and meat wrapped with pectin only. On the contrary, the results indicate that the incorporation of those ZnO nanoparticles induced significantly higher values of TBARS compared with unwrapped and pristine pectin-wrapped poultry meat (

p < 0.05). It was expected that the bionanocomposites made from tomato and passionfruit extracts would improve the polymer’s antioxidant activity, associated with the presence of phenolic compounds from those extracts [

65,

66], as was reported for apple peel extracts [

24]. However, the opposite was observed, and tomato extracts and passionfruit extracts showed a pro-oxidant effect. The same was also reported by other authors. Kenar et al. [

67] showed that sardine fillets treated with sage tea extracts showed significantly higher MDA values compared to the control, thus indicating that sage tea extracts presented pro-oxidant activity.

Concerning the hue angle, the initial colour was 55°, which represents a reddish-orange colour. This poultry meat presented a value that was more reddish than the value of poultry meat presented by Souza et al. [

24], which was more orange than reddish. During refrigerated storage, unwrapped poultry meat maintained the same value, indicating that the characteristic reddish-orange color of poultry meat was maintained in spite of its deterioration. Concerning wrapped meat, all the samples increased (

p < 0.05) the hue angle to 60–63° , which indicates a change in the poultry meat colour to a more orange colour than red. Yet, at day 15, only hue angle values of poultry meat wrapped with pectin incorporated with zinc oxide nanoparticles obtained from tomato extracts (ZnO-TNPs) were significantly (

p < 0.05) higher than the hue angle of unwrapped poultry meat. The other wrapped samples presented a higher hue angle than unwrapped poultry meat, but the difference was not significant (

p > 0.05). At day 11, no significant differences were observed between wrapped and unwrapped poultry meat in terms of color. Hue angle is a parameter that translates the CIELab coordinators a* and b* into color, and values near 0° correspond to red, whereas higher values of about 90° correspond to yellow [

68]. Therefore, the change to a more orange than red color in the wrapped meat can be attributed to a decrease in the a* value during cold storage, which may have resulted from the oxymyoglobin oxidation to metmyoglobin [

55]. This oxidative process is also well correlated with the TBARS results, which showed higher values in poultry meat wrapped with pectin incorporated with ZnO nanoparticles synthesized with tomato and passionfruit extracts, which exhibited pro-oxidant activity. A comparison made with other studies reported in the literature shows that this pro-oxidant behavior is not the typical trend observed when meat is being wrapped with a biobased film incorporated with ZnO nanoparticles. Indeed, in the study by Suo et al. [

55], fresh pork meat wrapped with ZnO nanoparticles inserted in CMC protected samples from discoloration. The same results were reported when fresh poultry meat was enveloped with chitosan incorporated with ZnO nanoparticles synthesized from apple peels [

24]. Therefore, poultry meat color preservation can be related to the antioxidant or pro-oxidant activity of the applied biobased films. Even so, and although wrapped poultry meat presented a more orange color than red than unwrapped poultry meat, the difference observed is not relevant enough to influence consumer choice once the colour is in the usual range of poultry meat colour (60°) [

24].