More news

- Nigeria’s paint industry navigates regulatory changes and economic challenges amid p...

- Focus on the global coatings market: Global coatings market outlook

- Innovative coatings mitigate effects of deepening climate change

- Ask Joe Powder – October 2024

- Chinese paint majors look to domestic consumer sales as commercial real estate slumps

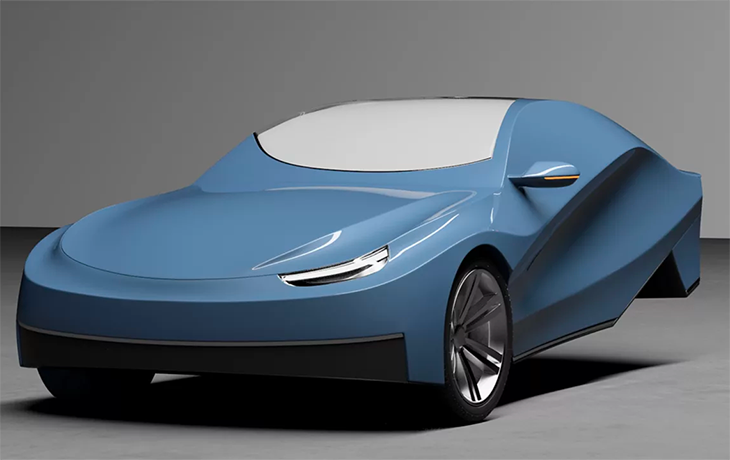

BASF’s ColorBrite® Airspace Blue ReSource basecoat, certified by REDcert² according to a biomass balance approach, made its debut in China. This is the first time BASF’s biomass balance automotive OEM coatings were introduced to Asia since the official launch in Europe in May of this year.

The first batch of ColorBrite Airspace Blue ReSource basecoat has been delivered to a customer in China. This basecoat product enables around 20% reduction in product carbon footprint. The saving number is reviewed by a third-party external sustainability consultant. Being part of the biomass balance version of BASF’s ColorBrite waterborne basecoat portfolio, ColorBrite ReSource adds a reduced carbon footprint without the need to alter the product’s formulation and performance.

BASF has also received the biomass certification for its resins plant in Caojing, as well as its paint manufacturing sites in Minhang and Caojing operated by BASF Shanghai Coatings Co., Ltd. With this certification, BASF has the capability to provide its customers in China a comprehensive range of biomass balance certified automotive coatings solutions using materials derived from renewable raw materials.

“Replacing fossil-based feedstock with renewable raw materials through BASF’s biomass balance approach symbolises our pledge to helping our customers achieve their carbon emission targets while retaining the same high quality and performance of the product. The biomass balance approach certification for our sites in China reinforces our commitment of being an industry leader in driving sustainability and innovation. We look forward to cooperating with more OEMs in China by contributing to a resource-efficient and carbon-neutral future together,” said Jack Zou, Vice President, Automotive OEM Coatings Solutions Asia Pacific, BASF.

In BASF’s biomass balance approach, renewable raw materials are used as raw materials when manufacturing primary chemical products in the production site. The proportion of renewable raw materials is then attributed to certain sales products according to a certified mass balance method. REDcert² is a certification system for the sustainable use of biomass, which confirms that BASF has replaced the quantities of fossil resources required for the biomass balanced product sold with renewable raw materials.