More news

- Focus on supply chain: How AI can transform your supply chain network

- Focus on Extenders & Fillers: Improving corrosion resistance of polyester powder coat...

- Focus on Extenders & Fillers: Coatings for sub-ocean equipment without solvents

- Ask Joe Powder August 2024 – Defects and the matter of VOCs

- Water for the production of waterborne paints and coatings tests

Special paint supply systems make a virtually unlimited number of paint colours available quickly, economically and without residue. Paint supply systems for special colours with low production rates are more economical and sustainable for industrial painting than conventional ring-pipe systems. These systems significantly minimise paint loss, waste and rinsing agent consumption. This paint supply method has already proved beneficial in the automotive painting world, and Dürr has gone one step further by enhancing it for use in other industries for the first time

The desire for a comprehensive colour palette extends beyond the automotive industry. Customers use their colour preferences as unique identifiers, whereas companies use distinctive colours as a unique selling point for themselves and their products. Manufacturers from the construction, woodworking, plastic or automotive supplier industries, for example, require a multitude of available shades to cater to their customers’ needs. Special paint supply systems facilitate this extensive colour range and offer enormous savings potential in all branches of industry. This approach is both more sustainable and cost-effective in accommodating an expanding variety of colours than conventional ring-pipe systems.

High costs for small-batch colours

A look at production rates of paint shop colours highlights the potential for cost and resource savings with special paint supply systems. Analyses conducted by various car manufacturers indicate that more than 90% of the total production volume comprises no more than 10 colours, meaning that the remaining colours – many used only once a day or even less frequently—make up a negligible percentage of the total production volume. This phenomenon can be transferred to other industries. Many products are available in common standard colours, but individual customer requests are also possible. In such cases, the colours are sometimes only used once in several weeks or months.

Traditionally, most paint shops employed several conventional ring-pipe systems to apply small-batch colours with low production rates. This approach makes no economic or ecological sense, since the liquid paints require constant motion to prevent colour pigments from settling. Mechanical forces cause shearing during circulation, negatively impacting the properties of complex paints. Rarely used colours, which receive minimal fresh material, quickly reach critical levels, negatively affecting paint quality. Fresh paint must be added at regular intervals to ensure the quality of these rarely used colours. However, since only a small quantity of paint is used at one time, appropriate quantities must be disposed of to maintain the paint quality.

On the other hand, special paint supply systems store the necessary paint colours in climate-controlled paint mixing rooms and do not provide them to the painting robot until right before the painting item enters the paint booth. Since shearing does not negatively impact paint quality, it minimises paint loss – and hazardous waste. Supplying paint via ring-pipe systems, therefore, only makes sense for the manufacturer’s standard colour as well as a few other colours with production rates higher than five percent. A maximum of 10 ring-pipe systems are needed for this. For all other colours, a special paint supply system is not only more cost-effective to operate, but also more sustainable.

READ MORE:

Beckers Group appoints Nicklas Augustsson Chief Sustainability Officer

Special paint supply systems beneficial for budgets and the environment

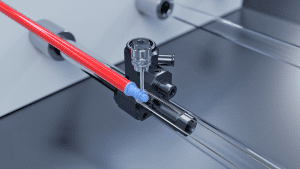

Given the sharp increase in paint prices, particularly for special paints, piggable systems for supplying special paint colours pay for themselves rapidly through the almost complete recovery of the unused paint. A single system can provide unlimited colours consecutively for application, offering unparalleled flexibility. Specially designed components, known as ”pigs”, precisely match the internal diameter of the hoses – pushing the paint to the colour changer and, after painting, pushing the leftover paint back into the paint container. Since the entire process leaves no residue, cleaning is unnecessary, reducing both paint and rinsing agent consumption – beneficial for budgets and the environment. Special colour supply system efficiency is also the result of fast colour changes. While it takes days to switch a ring-pipe system to a new colour, the special paint supply system accomplishes this in 10-20 minutes, depending on parameters such as length of paint hose to the robot and number of robots installed. The modular special paint supply system is suitable for processing both water-based and solvent-based paints.

Caption: Fast pig, fast colour changes. The pig pushes the leftover paint back into the container, leaving no residue

Caption: The source station (shown here) is the pig’s starting point. The material pushes the pig from the source station through the distributor station to the destination station

ready2integrate: Special paint supply system via plug and play

The modular design simplifies maintenance, allowing flexible configuration of individual components to adapt to user requirements. For years, Dürr has pursued its ready2integrate concept, aiming to seamlessly align individual products – from control unit to applicator – to swiftly assemble a high-quality painting solution. Thus, the special paint supply systems can also integrate with other Dürr systems, such as the paint supply station.

Caption: Set-up of a special colour supply system

Thanks to their modularity, the systems are flexible and suitable not only for newly built but also for existing painting systems. For example, when updating an existing system, it makes sense to replace the existing ring-pipe systems – especially for colours with low production rates – with a special paint supply system. The system’s benefits include minimal paint loss, low rinsing agent consumption, extremely short colour change times and lower environmental impact due to less waste.

Dürr Systems AG: www.durr.com